This potato chips production line consists of lifting feeder — macchina per la rimozione delle pietre per la pulizia dei rulli — lifting machine — pelatrice a spazzola — manual selection conveyor belt — quantitative lifting feeder — slicing machine — macchina per la pulizia delle bolle d'aria — air blown stranding machine – friggitrice continua di tipo rotativo – lifting selection conveyor — vibration feeder – roller mixing machine — finished product conveyor –420 Tipo Confezionatrice automatica — pressione dell'aria Meccanismo macchina per azoto – cercametalli – macchina sigillatrice.

Processo di lavorazione

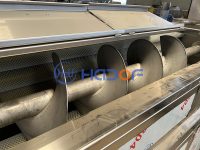

1.Potato Washing and Peeling: The process begins with the cleaning and peeling of the raw potatoes. With the help of roller cleaning stone removal machine and brush peeling machine, this stage can remove dirt, impurities, and the outer skin of the potatoes.

2.Potato Slicing: The peeled potatoes are sliced into thin, fette uniformi con l'affettatrice. Consistency in thickness is important to ensure even frying and consistent product quality. La nostra affettatrice ha le caratteristiche di una superficie liscia, taglio veloce, Facile pulizia e funzionamento semplice, che può far risparmiare manodopera e costi.

3.Air Bubble Cleaning: The cleaning time is 30-40S. During the cleaning process, the starch and sugar on the surface of potato chips can be removed to prevent the deterioration of the oil body and prolong the service life of the oil.

4.Sbollentare: La sbollentatura è una procedura necessaria. Put the potato slices into the blanching machine with a water temperature of about 65-90℃, che può distruggere l'attività enzimatica, migliorare e ammorbidire la struttura dei tessuti, Rendilo facile da asciugare, e previene anche la frittura e la formazione di schiuma.

5.Essiccazione: Drying the moisture on the surface of the potato chips can effectively reduce the oil content of the potato chips during frying, improve the taste of the potato chips, and reduce the energy consumption of frying.

6.Frittura: Il tempo di frittura è 2-3 minuti e la temperatura di frittura è di 170-180°C. The dried potato slices are deep-fried in oil at controlled temperatures until they become crispy and golden brown.

7.Condimento: Dopo la frittura, Le patatine possono essere condite con vari aromi come il sale, spezie, o altri aromi. This can be achieved through a seasoning drum machine.

8.Imballaggio: The final step is to package the potato chips into bags, Sacchetti, o contenitori. 420 Tipo La macchina automatica per il confezionamento garantisce una corretta sigillatura e protezione del prodotto per mantenere la freschezza e prolungare la durata di conservazione.

Macchine per la lavorazione alimentare HAOF, forno di essiccazione usato

Macchine per la lavorazione alimentare HAOF, forno di essiccazione usato

Hello sir, I need a natural potato production line with a production capacity of 300 tons per hour with all the details and it must be fully automatic. We are thankful for your cooperation with us. I am Bakil Soufan, the correspondence officer for the Yemeni Food Industries Company.

For my cassava processing business, I want to know the price of cassava peeler, machine, cassava splicing machine and cassava dryer machine.

Dear

My nees 100 kg daily autio production patoto chips line matchin, pls cost estimate & machine Detail

Sayedmasud.bd@gmail.com

Dear

My needs 100 kg daily auto production Natural patoto chips line matchin, pls cost estimate & machine Detail

Sayedmasud.bd@gmail.com

Ok

Good morning, l am looking for a extruder to manufacture puff an corn products.

Bonjour

Nous cherchons dès lignes de production de frites et outre légumes.

Merci de nous répondre rapidement merci

Please furnish me with the price of whole chips making machinery including packaging in poly bags of various sizez

How can I get the product

Hi.i plan to buy this production line and export to oman.i am interested to know how much cost this production line. Thanks

beef meat dumpling production

Hello together,

i need a production line for french fries complete.

can make me a Offre EX Works to Tunesia port Tunis.

the Heating should be with Gas.

the Capacity should Min 100kg/h to more.

Best Regards

Ahmed Hachem

Nice and wonderful

Last price please

Would love to use you product to create my brand

I need the complete process machines for making potatoes, plantain and other chips machines.

Moderate prices please.

Thanks

Very impressed. Can I have catalogue if you have any with details of the line such as dimensions. Also, if you can show the maximum area the line can occupy. Thank you in advance.

I want to know how much the machine cost . I want to open chips company in Africa.

Please send me your price for the potatoes processing machine